Ralph Mills

Nottingham lace machines

| ENLARGE |

A collection of images in Nottingham Industrial Museum

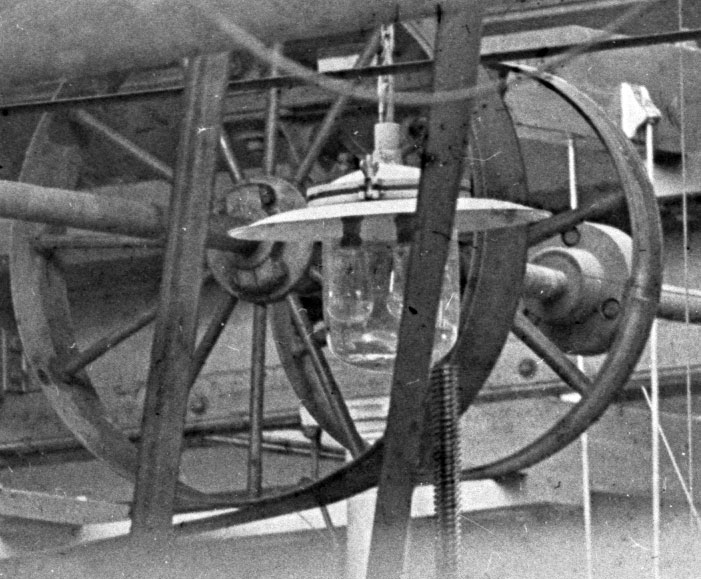

When I was a volunteer at Nottingham Industrial Museum I was given the pleasurable task of scanning a number of glass negatives of lace machines. It was repetitive, but fascinating and rewarding work. I was told that each machine was first fully assembled in the factory. Then, because they were often destined for export, and because they were so large and complex, they were taken apart and shipped in pieces. Photographs were taken to assist the engineers in rebuilding them on site. These are just a few examples. (Figures 1 to 4)

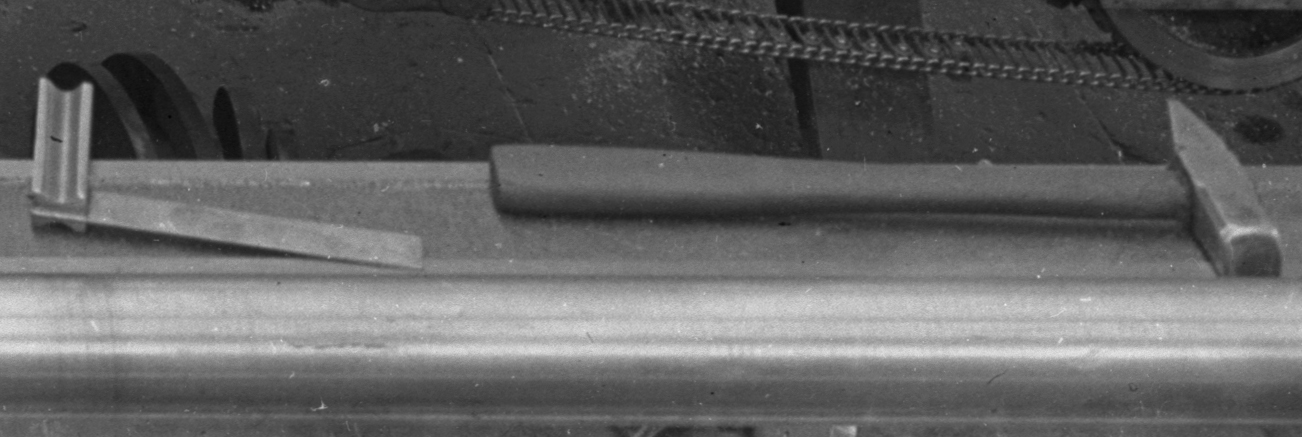

Taken using long exposures and small apertures, the 6.5 x 4.5 inch negative are incredibly detailed. For example, in Figure 13 you can make out a rack of tools in the background (enlarged in Figure 14). I enlarged and explored many of the images: the details of the machines mean nothing to a non-engineer, but neverthless show what amazing feats of mechanical engineering they were. And of course Jacquard lace machines used an early form of punched card programming. However it was what was going on in the backgrounds of the photographs that really grabbed my attention — glimpses of the interiors of the factories, of the belts and pullies that powered the machinery, and the occasional more human detail, like a ghostly flat cap.

| ENLARGE |

Women take over the lathes.

During the First World War, lace-making factories changed to making munitions, and because the majority of younger men were otherwise engaged, women were employed on the factory floors. Figures 13—27 show some images from that period.

Sadly, most lace machines were broken up, simply smashed to pieces using sledge hammers, when they were no longer used. However there are a few examples of small machines in Nottingham Industrial Museum.

| ENLARGE |

Updated on 18th January 2022

Making the machines

| ENLARGE |

| ENLARGE |

| ENLARGE |

| ENLARGE |

n | ENLARGE |

| ENLARGE |

| ENLARGE |

| ENLARGE |

| ENLARGE |

| ENLARGE |

| ENLARGE |

From lace to munitions

| ENLARGE |

| ENLARGE |

ENLARGE |

| ENLARGE |

| ENLARGE |

| ENLARGE |

| ENLARGE |

| ENLARGE |

| ENLARGE |

| ENLARGE |